Customized Control

Panel:

Customized control panel is a tailored control system designed specifically to meet the unique requirements of a particular machine or production process. Unlike standard control panels, which are built for general applications, a customized control panel is engineered to address the specific operational, safety, and efficiency needs of a specific machine or set of machines.

Key Features of a Customized Control Panel:

Tailored Design:

- The panel layout, component selection, and interface design are customized to fit the exact specifications of the machine and the operational environment. This ensures that the control panel integrates seamlessly with the machine’s functionality.

- The panel layout, component selection, and interface design are customized to fit the exact specifications of the machine and the operational environment. This ensures that the control panel integrates seamlessly with the machine’s functionality.

Specific Functionality:

- Custom control panels are designed to manage and control the precise operations of a machine, whether it’s for automation, process control, or manual operation. This could include specialized controls, sensors, or feedback systems unique to the machine’s tasks.

- Custom control panels are designed to manage and control the precise operations of a machine, whether it’s for automation, process control, or manual operation. This could include specialized controls, sensors, or feedback systems unique to the machine’s tasks.

Advanced Automation:

- Depending on the application, the control panel can incorporate advanced automation features such as PLC (Programmable Logic Controller) programming, SCADA (Supervisory Control and Data Acquisition) systems, or custom algorithms to optimize machine performance.

- Depending on the application, the control panel can incorporate advanced automation features such as PLC (Programmable Logic Controller) programming, SCADA (Supervisory Control and Data Acquisition) systems, or custom algorithms to optimize machine performance.

Integration with Existing Systems:

- Customized panels can be designed to integrate with existing industrial systems, such as other machinery, networked control systems, or factory automation protocols (e.g., Modbus, Ethernet/IP, etc.). This ensures seamless communication and coordination between different parts of a production line.

- Customized panels can be designed to integrate with existing industrial systems, such as other machinery, networked control systems, or factory automation protocols (e.g., Modbus, Ethernet/IP, etc.). This ensures seamless communication and coordination between different parts of a production line.

Safety Features:

- Safety is a critical aspect of customized control panels. They are often equipped with emergency stop buttons, interlocks, safety relays, and other safety devices tailored to the specific risks associated with the machine’s operation.

- Safety is a critical aspect of customized control panels. They are often equipped with emergency stop buttons, interlocks, safety relays, and other safety devices tailored to the specific risks associated with the machine’s operation.

Environmental Considerations:

- The control panel can be built to withstand specific environmental conditions, such as dust, moisture, extreme temperatures, or corrosive environments, ensuring reliable operation in challenging conditions.

- The control panel can be built to withstand specific environmental conditions, such as dust, moisture, extreme temperatures, or corrosive environments, ensuring reliable operation in challenging conditions.

Energy Efficiency:

- Custom panels can include features that optimize energy usage, such as variable frequency drives (VFDs) for controlling motor speeds, energy monitoring systems, or automated shutdown sequences when the machine is not in use.

- Custom panels can include features that optimize energy usage, such as variable frequency drives (VFDs) for controlling motor speeds, energy monitoring systems, or automated shutdown sequences when the machine is not in use.

Scalability and Future-Proofing:

- Designed with future needs in mind, customized control panels can be easily upgraded or expanded to accommodate new functionalities, additional machines, or evolving production requirements.

Common Applications of Customized Control Panels:

Manufacturing and Production Lines:

- Custom control panels are often used to manage complex machinery and production processes, ensuring precision, consistency, and efficiency.

- Custom control panels are often used to manage complex machinery and production processes, ensuring precision, consistency, and efficiency.

Packaging Machines:

- Control panels tailored for packaging machines can handle specific tasks such as timing, labeling, sealing, and quality control, often integrating with sensors and automated handling systems.

- Control panels tailored for packaging machines can handle specific tasks such as timing, labeling, sealing, and quality control, often integrating with sensors and automated handling systems.

CNC (Computer Numerical Control) Machines:

- CNC machines often require customized control panels to manage precise cutting, drilling, or milling operations, with interfaces that allow for programming and monitoring of complex patterns.

- CNC machines often require customized control panels to manage precise cutting, drilling, or milling operations, with interfaces that allow for programming and monitoring of complex patterns.

Robotics and Automation:

- In robotics, custom control panels are designed to handle intricate tasks, coordinate multiple axes of movement, and integrate with sensors, vision systems, and other automation tools.

- In robotics, custom control panels are designed to handle intricate tasks, coordinate multiple axes of movement, and integrate with sensors, vision systems, and other automation tools.

Specialized Equipment:

- Custom panels are essential for specialized machinery used in industries like pharmaceuticals, food processing, textiles, and aerospace, where unique operational requirements must be met.

Benefits of Customized Control Panels:

Enhanced Efficiency: Optimized for the specific machine, these panels ensure that all operations are performed with maximum efficiency.

- Improved Safety: Tailored safety features reduce the risk of accidents and ensure compliance with industry standards.

- Greater Flexibility: Customization allows for greater adaptability to changing production needs or technological advancements.

- Ease of Use: A user-friendly interface designed with the operator in mind improves usability and reduces the potential for human error.

- Cost-Effective: While there is an initial investment, the long-term benefits of reduced downtime, lower energy consumption, and improved productivity often justify the cost.

Recommendation:

A customized machine control panel is a critical component in any specialized machinery setup, providing the necessary control, safety, and efficiency for optimal operation. By tailoring the panel to the specific needs of the machine and its environment, manufacturers can achieve greater precision, reliability, and productivity.

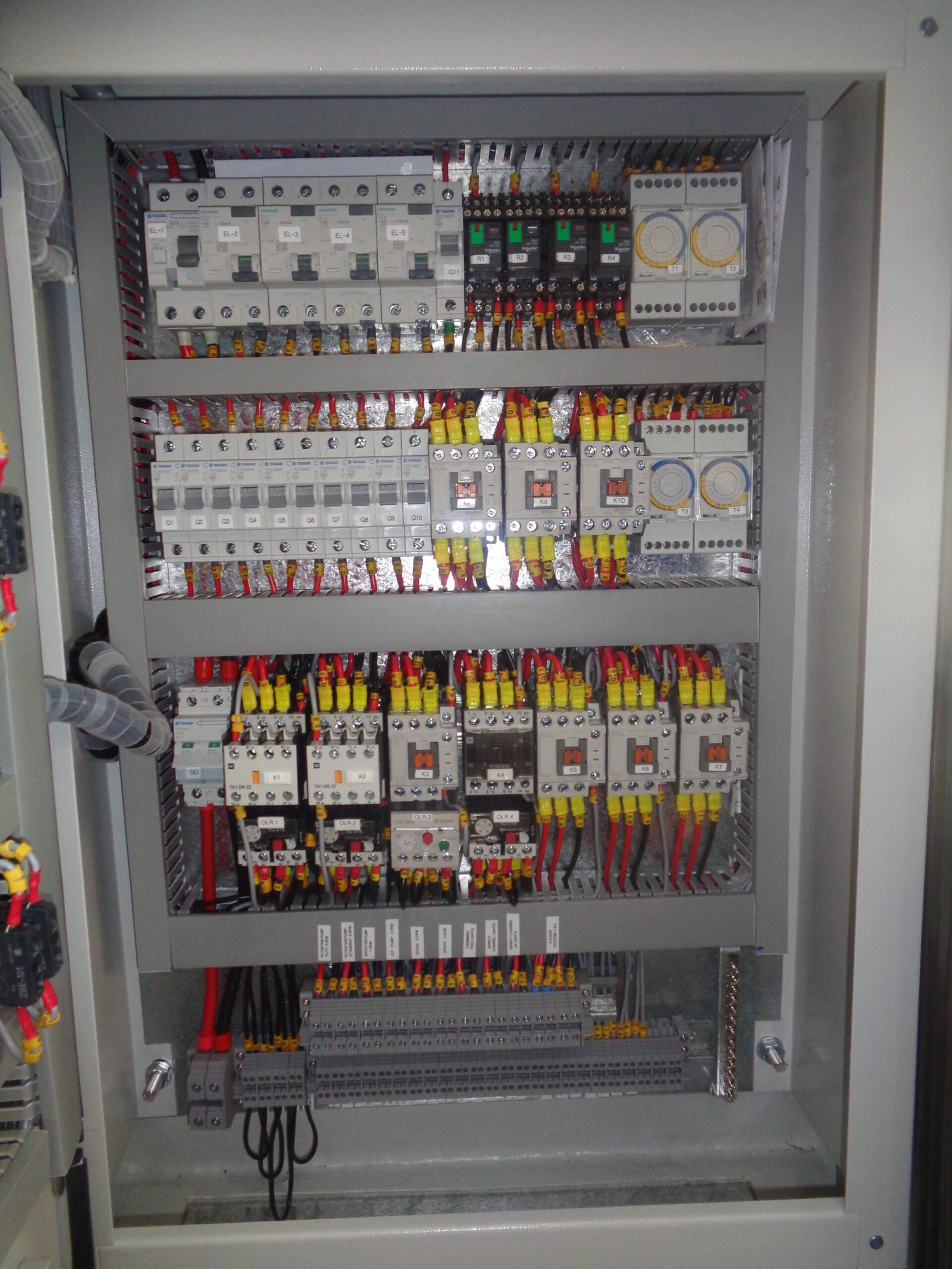

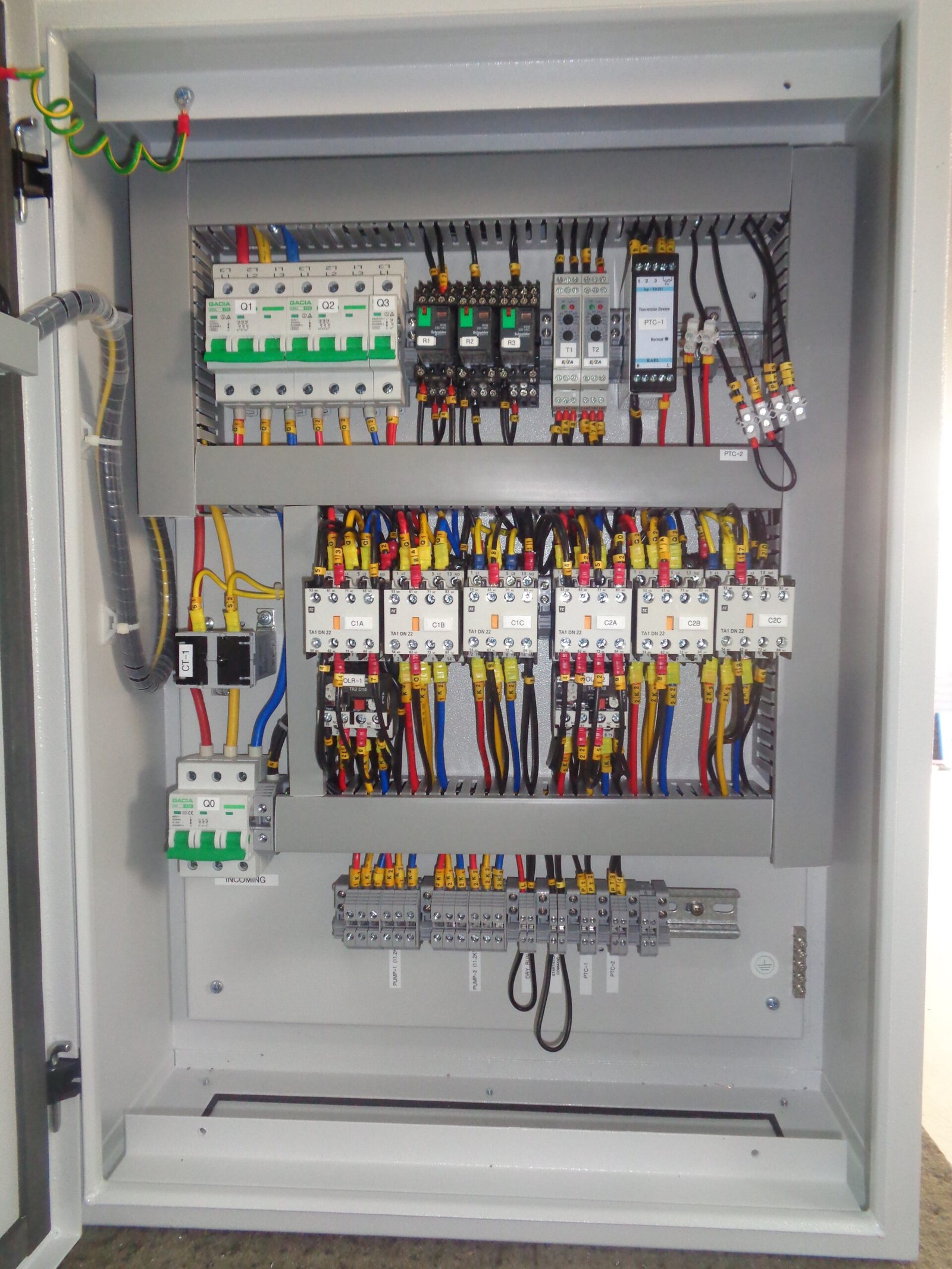

Photo Gallery