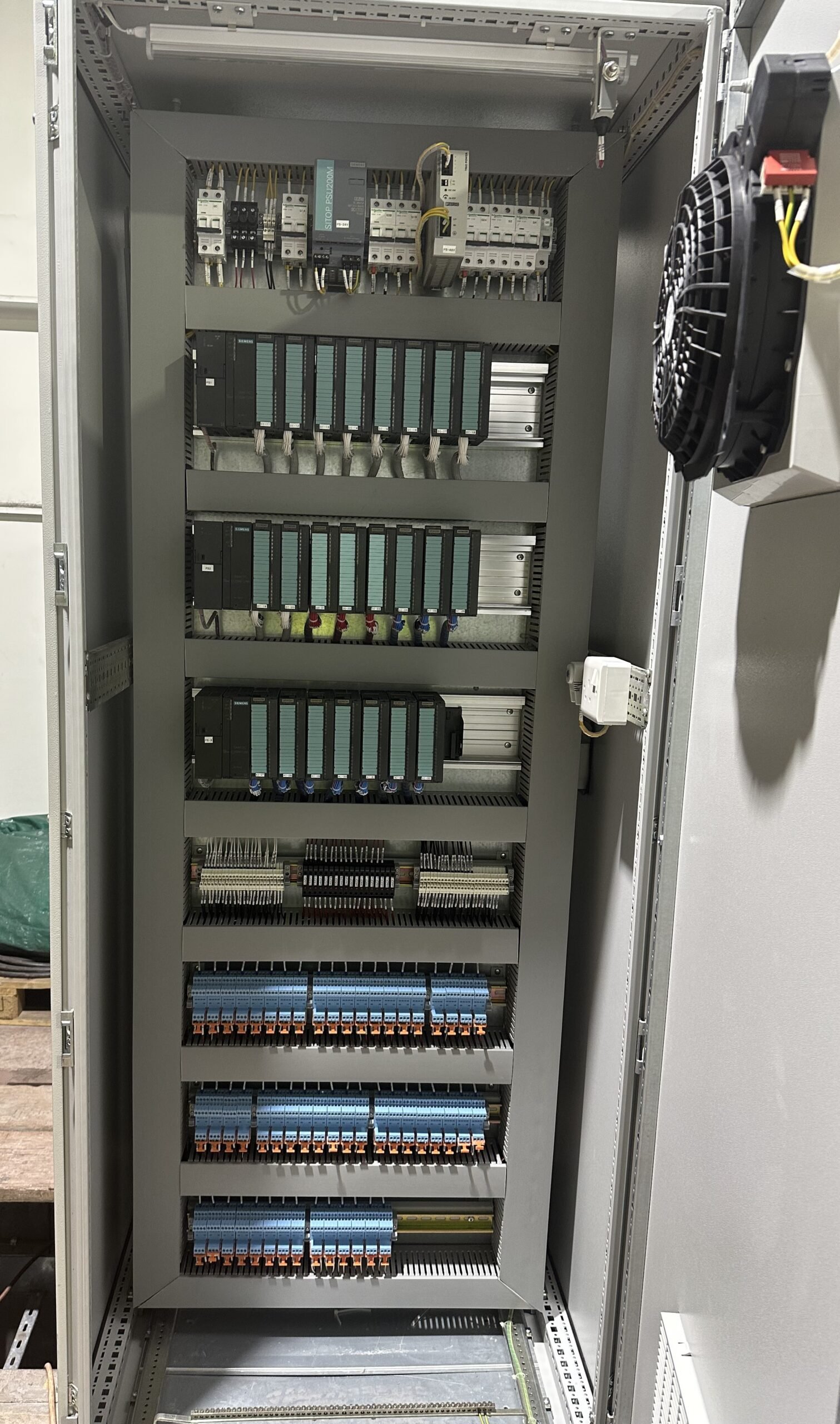

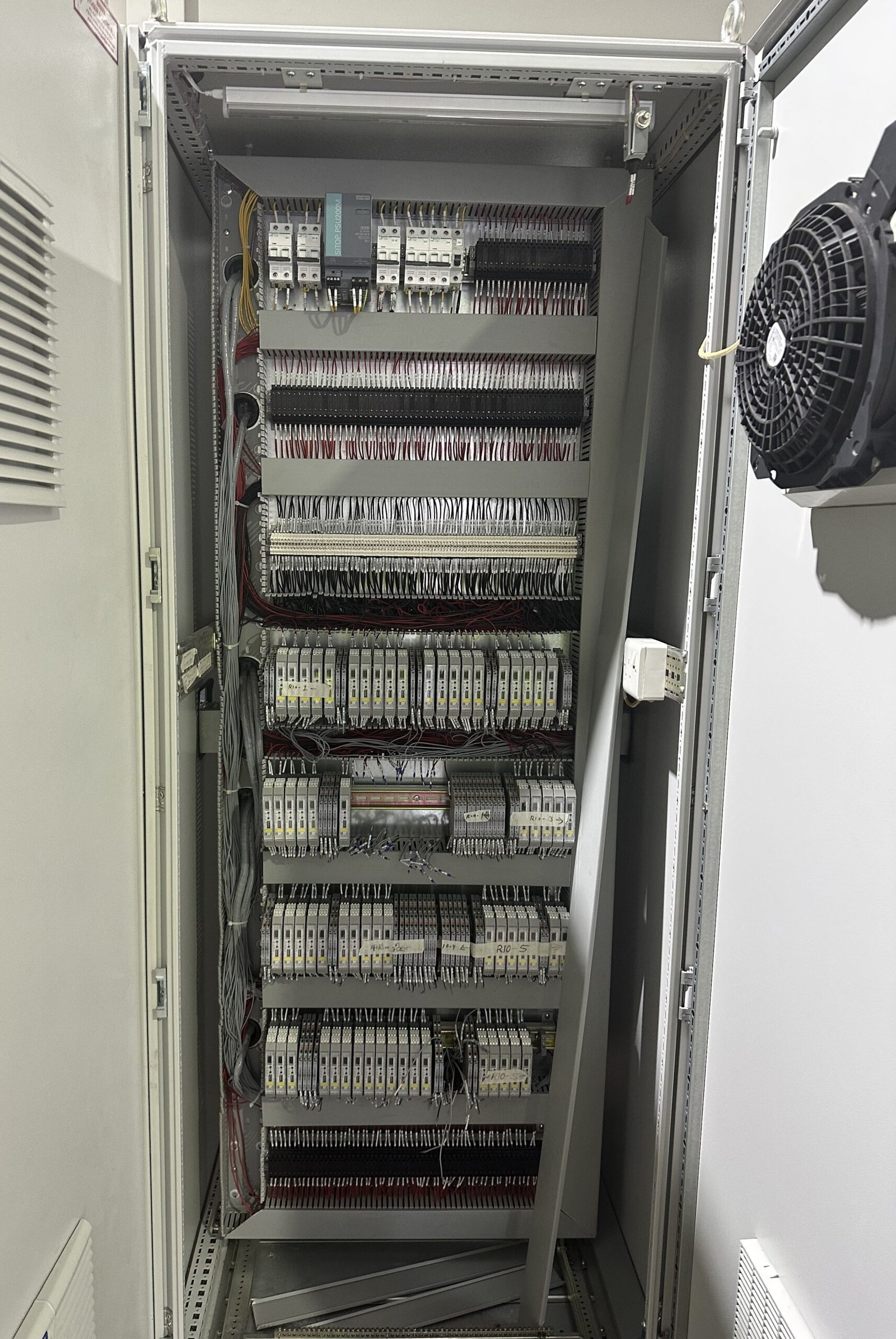

PLC and VFD Panel:

Programmable Logic Controller

(PLC) Panel:

A Programmable Logic Controller (PLC) Panel is an essential component in industrial automation, designed to control and monitor various industrial processes and machinery. Here’s a brief overview

Components:

- PLC: The heart of the panel, responsible for executing control logic. It consists of a CPU, memory, input/output (I/O) modules, and communication interfaces.

- Power Supply: Provides the necessary power to the PLC and other components within the panel.

- I/O Modules: Interface between the PLC and field devices such as sensors (inputs) and actuators (outputs).

- Communication Modules: Enable the PLC to communicate with other devices, systems, or networks, often using protocols like Ethernet, Modbus, or Profibus.

- HMI (Human-Machine Interface): Allows operators to interact with the PLC, monitor processes, and make adjustments as needed.

- Circuit Protection Devices: Include breakers, fuses, and surge protectors to safeguard the panel and connected devices from electrical faults.

- Terminal Blocks: Facilitate wiring and connections between the PLC, field devices, and other components within the panel.

- Enclosure: Protects the internal components from environmental factors like dust, moisture, and heat, often rated according to IP standards.

Functionality:

- Automation Control: The PLC executes programmed logic (ladder logic, structured text, etc.) to control machines, processes, and systems in real-time.

- Data Acquisition: Collects data from sensors and devices, which can be used for monitoring, analysis, and optimization of processes.

- Process Monitoring: Provides real-time status updates, alerts, and alarms to operators via the HMI or SCADA (Supervisory Control and Data Acquisition) systems.

- Flexibility and Scalability: Easily reprogrammed or expanded to accommodate changes in the production process or system upgrades.

Applications:

- Manufacturing: Controlling assembly lines, robotic systems, and machinery.

- Energy Management: Managing power distribution, load shedding, and energy efficiency.

- Water Treatment: Monitoring and controlling pumps, valves, and chemical dosing systems.

- Building Automation: Managing HVAC systems, lighting, and security.

- Oil & Gas: Supervising drilling operations, pipeline control, and safety systems.

A PLC panel is vital for enhancing efficiency, reliability, and safety in industrial operations. It enables precise control, reduces human intervention, and allows for seamless integration with other automation systems.

Variable Frequency Drive

(VFD) Panel:

A Variable Frequency Drive (VFD) panel is an essential component in industrial and commercial settings where motor control is crucial. Here’s a brief overview:We are fortunate to supply plenty of VFD Panel in this region and its working without any trouble. We have our own dedicated design team to work on all these type of panels.

What is a VFD Panel?

A VFD panel is an assembly that houses a Variable Frequency Drive, along with other necessary electrical components, to control the speed and torque of electric motors. The primary purpose of a VFD is to adjust the motor’s operating speed by varying the frequency and voltage supplied to the motor.

Key Components:

- VFD Unit: The core component that controls the frequency and voltage supplied to the motor.

- Circuit Breakers: Protects the system from overloads and short circuits.

- Contactors: Control the starting and stopping of the motor.

- Relays: For protection and control purposes.

- HMI (Human Machine Interface): Allows operators to interact with the VFD for monitoring and control.

- Cooling Fans/Filters: Maintains optimal operating temperatures inside the panel.

Applications:

- Pumps and Fans: For controlling flow rates and saving energy.

- Conveyors: To control the speed and reduce wear and tear on the system.

- HVAC Systems: For efficient energy management and system control.

- Compressors: To optimize performance and reduce energy consumption.

Benefits:

- Energy Savings: By optimizing motor speed and reducing power consumption.

- Extended Equipment Life: Smooth start/stop operations reduce mechanical stress on motors.

- Improved Process Control: Precise speed and torque control for better process management.

- Reduced Maintenance Costs: Less mechanical stress leads to fewer breakdowns.

VFD panels are widely used in various industries such as manufacturing, water treatment, HVAC, and more. They are vital for enhancing the efficiency, control, and longevity of motor-driven systems.